Umatshini wokwenza iphepha le-Xinnuo Galvanized,

Umatshini wokwenza umqulu wentsimbi,

| HAYI. | Iparameter engundoqo yesixeko saseBotou ungqinisiso olufanelekileyo lwe-828 i-automatoc cinezela ibhlowu yenza i-joists ekhazimlisiweyo yentsimbi yophahla lwethayile ephuma kumatshini onece | |

| 1 | Ifanelekile ukuqhutyelwa phambili | Ipleyiti yentsimbi enombala |

| 2 | Ububanzi bepleyiti | 1000mm |

| 3 | Ukutyeba kwepleyiti | 0.3-0.7mm |

| 4 | De-coiler | Incwadi yokuqala, inokulayisha iitoni ezi-5 zemathiriyeli ekrwada |

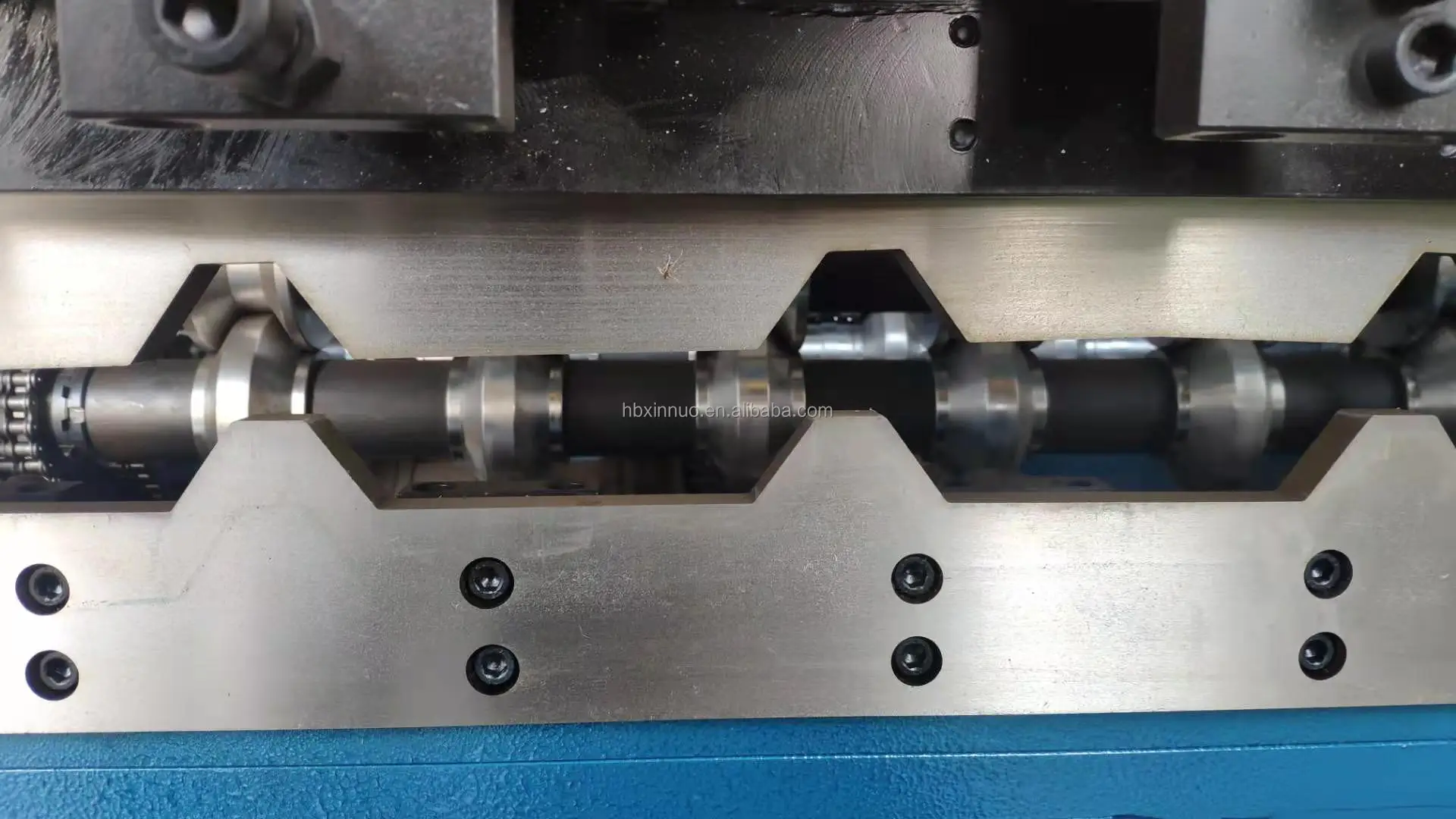

| 5 | Iirola zokubumba | 12 imiqolo |

| 6 | Ububanzi be-roller | 80mm |

| 7 | Izinto eziqengqelekayo | Intsimbi yeCarbon 45# |

| 8 | Amandla enjini aphambili | 4kw |

| 9 | Imveliso | 0-3m/min |

| 10 | Indlela yokusika | I-Hydraulic kunye nesikhokelo sokusika intsika |

| 11 | Izinto eziphathekayo ze-blade yokusika | Cr12 |

| 12 | Amandla okusika i-hydraulic | 3kw |

| 13 | Ukusetyenzwa ngokuchanekileyo | Ngaphakathi kwe-1.00mm |

| 14 | Inkqubo yokulawula | Ulawulo lwe-Delta PLC |

| 15 | Iphaneli yecala lomatshini | 14mm |

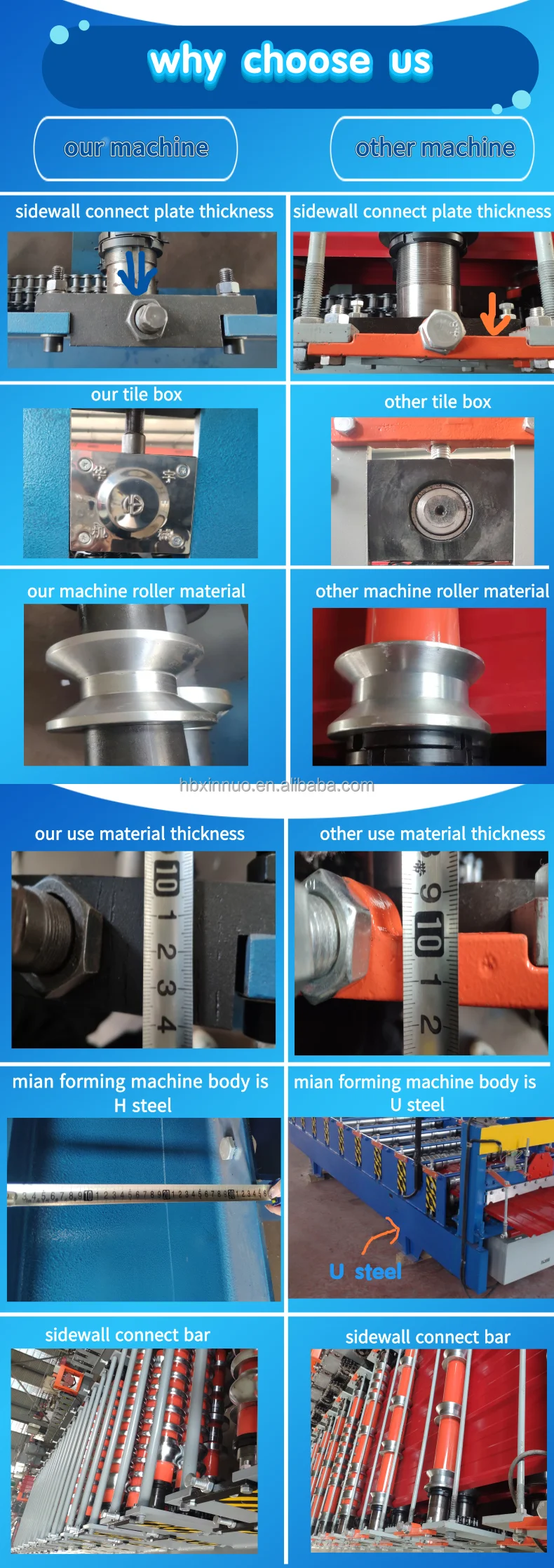

| 16 | Ubume obuphambili bomatshini | 300 H intsimbi |

| 17 | Ubunzima | Malunga ne-4.0T |

| 18 | Imilinganiselo | 7.0*1.5*1.55m |

| 19 | I-Voltage | 380V 50Hz 3 izigaba (ezitshintshekayo njengoko iimfuno) |

| 20 | Isatifikethi | CE/ISO |

| 21 | Isiko | Ngokweemfuno zomthengi |

| Iinkcukacha zokuPakisha: | Umatshini oyintloko uhamba ze, ibhokisi yokulawula ikhompyutha igcwele isakhelo somthi. |

| Umatshini oyintloko unqunu kwisikhongozeli, ibhokisi yokulawula ikhompyutha igcwele ukupakishwa kwamaplanga. | |

| Iinkcukacha zohambiso: | Iintsuku ezingama-20 |

Ngophuhliso oluqhubekayo lwesayensi kunye nobuchwepheshe, izixhobo ezahlukeneyo kwimveliso yemizi-mveliso nazo zihlaziywa rhoqo. Phakathi kwabo, umatshini wokwenza ikhoyili yentsimbi, njengesixhobo esibalulekileyo sokuvelisa, usetyenziswa kakhulu kwiinkalo ezininzi. Eli nqaku liza kucacisa ngomatshini wokwenza amaphepha entsimbi.

I. Isishwankathelo

Umatshini wokwenza ikhoyili yentsimbi yinxalenye yesixhobo esenza iikhoyili zentsimbi zibe ziimo ezahlukeneyo kunye neenkcukacha. Umgaqo wayo wokusebenza kukucubungula i-iron sheet kwimilo efunekayo kunye nobukhulu ngokusebenzisa uchungechunge lokubumba kunye nezixhobo zoomatshini. Olu hlobo lwezixhobo lusetyenziswa ngokubanzi kulwakhiwo, ukwenziwa kweemoto, izixhobo zasekhaya kunye namanye amacandelo.

2. Umgaqo wokusebenza

Umgaqo osebenzayo womatshini wokwenza amaphepha entsimbi ubandakanya ikakhulu la manyathelo alandelayo:

Ukukhulula: Beka icwecwe lentsimbi kwisixhobo sokukhulula kwaye uyithumele kwindawo yokwenza ngesixhobo sokutsala.

Ukubumba: Kwindawo yokubumba, i-coil ye-sheet metal idlula kwi-series of forming dies kwaye icutshungulwe ibe yimo kunye nobukhulu obufunekayo. Ukubumba okubumba kunokutshintshwa njengoko kufunekayo ukuze kulungiswe kwiinkcukacha ezahlukeneyo kunye neemilo zeekhoyili zentsimbi.

I-Welding: Ngexesha lenkqubo yokuqulunqa, ukuba iikhoyili zentsimbi kufuneka zihlanganiswe kunye, oku kunokufezekiswa ngesixhobo sokudibanisa. Isixhobo se-welding sinokuhlengahlengiswa njengoko kufunekayo ukuze sihambelane neemfuno ze-welding ezahlukeneyo.

I-galvanizing: Emva kokwenza kunye ne-welding, i-coil sheet sheet inokuthi ifakwe i-galvanizing ukuphucula ukuxhathisa ukubola kunye nobomi benkonzo. Isixhobo sokukhenkceza sinokulungelelaniswa njengoko kuyimfuneko ukuze sihambelane neemfuno ezahlukeneyo zokugalela.

Ukupholisa: Emva kokugqiba inkqubo yokufaka i-galvanizing, i-iron sheet kufuneka ipholiswe ukuze izinze kwaye iphucule umgangatho wayo. Iyunithi yokupholisa inokulungelelaniswa njengoko kuyimfuneko ukuze ihambelane neemfuno ezahlukeneyo zokupholisa.

Ukubuyisela umva: Okokugqibela, amacwecwe entsimbi asetyenzisiweyo ayasongwa ukuze aqhutywe okanye ahanjiswe. Isixhobo sokujija sinokulungelelaniswa njengoko kufunekayo ukulungiselela iikhoyili zamaphepha entsimbi anemilinganiselo eyahlukeneyo kunye nobukhulu.

3. Iinkalo zesicelo

Njengesixhobo esibalulekileyo sokuvelisa, umatshini wokwenza amaphepha entsimbi asetyenziswa ngokubanzi kwiindawo ezininzi. Nazi ezinye zeendawo eziphambili zesicelo:

Intsimi yokwakha: Kwintsimi yolwakhiwo, oomatshini bokwenza amaphepha entsimbi basetyenziselwa ikakhulu ukwenza uphahla, iipaneli zodonga kunye nezinye izinto zokwakha zeemilo ezahlukeneyo kunye neenkcukacha. Ngenxa yokumelana nokugqwesa kwayo okugqwesileyo kunye nomgangatho olungileyo wenkangeleko, isetyenziswa kakhulu kwiintlobo ezahlukeneyo zeeprojekthi zokwakha.

Indawo yokwenza iimoto: Kwindawo yokwenziwa kweemoto, oomatshini bokwenza amaphepha entsimbi basetyenziswa ikakhulu ukwenza imizimba yeemoto, iingcango kunye nezinye izinto. Ngenxa yamandla ayo abalaseleyo kunye nokuqina, ihlangabezana neemfuno eziphezulu zokwenziwa kweemoto.

Intsimi yoshishino lwezixhobo zasekhaya: Kwintsimi yoshishino lwezixhobo zasekhaya, oomatshini bokwenza amaphepha entsimbi basetyenziswa ikakhulu ukwenza iikheyibhile zezixhobo zasekhaya kunye neenxalenye zeemilo ezahlukeneyo kunye neenkcukacha. Ngenxa yomgangatho wayo omhle wenkangeleko kunye nokumelana nomhlwa, inokuhlangabezana neemfuno zezixhobo zekhaya.

Eminye imimandla: Ukongeza kule mimandla ingentla, oomatshini bokwenza amaphepha entsimbi basetyenziswa ngokubanzi kwishishini lemichiza, i-petroleum, ishishini lokukhanya kunye nezinye iindawo apho iimveliso zetsimbi zeemilo ezahlukeneyo kunye neenkcukacha ezifunekayo.

4. Isiphelo

Ukushwankathela, umatshini wokwenza ikhoyili yentsimbi, njengesixhobo esibalulekileyo sokuvelisa, usetyenziswa kakhulu kwiindawo ezininzi. Njengoko iteknoloji iqhubeka nokuphuhlisa, ukusebenza kwayo kunye nomgangatho nazo ziphucula rhoqo. Kwixesha elizayo, kunye notshintsho kwimfuno yemarike kunye nokuqhubela phambili kwezobuchwepheshe, oomatshini bokubumba amaphepha entsimbi baya kuqhubeka nokudlala indima ebalulekileyo ekuboneleleni ngenkxaso eqinile kwimveliso kunye nophuhliso lwamashishini ahlukeneyo.

♦ INKONZO YENKAMPANI:

Hebei Xinnuo Roll Ukwenziwa Machine Co., Ltd., hayi kuphela ukuvelisa iintlobo ezahlukeneyo zoomatshini umqulu ukwenza umqulu, kodwa nokuphuhlisa imigca yemveliso okrelekrele oluzenzekelayo umqulu, C&Z imilo koomatshini purline, uhola wendlela guardrail umqulu ukwenza imigca umatshini, imigca sandwich panel imveliso imigca, decking oomatshini bokubumba, oomatshini bokukhanya, oomatshini bokwenza ucango lwe-shutter slat, oomatshini bombhobho osezantsi, oomatshini bokugalela amanzi, njl.

Izinto eziluncedo kwiRoll Ukwenza iMetal Part

Kukho iingenelo ezininzi zokusebenzisa ukwenza umqulu kwiiprojekthi zakho:

- Inkqubo yokwenza umqulu ivumela imisebenzi efana nokubetha, ukubethelwa, kunye ne-welding ukuba yenziwe e-line. Iindleko zomsebenzi kunye nexesha lemisebenzi yesibini ziyancitshiswa okanye zipheliswe, ukunciphisa iindleko zenxalenye.

- Isixhobo sokwenza umqulu sivumela iqondo eliphezulu lokuguquguquka. Isethi enye yezixhobo zefom ye-roll iya kwenza phantse naluphi na ubude becandelo elifanayo elinqamlezayo. Iiseti ezininzi zezixhobo zeendawo ezahlukeneyo zobude azifuneki.

- Inokubonelela ngolawulo olungcono lwe-dimensional kunezinye iinkqubo zetsimbi ezikhuphisanayo.

- Ukuphindaphinda kungokwemvelo kwinkqubo, ukuvumela ukudityaniswa lula kwamalungu aqulunqwe kwimveliso yakho egqityiweyo, kunye nokunciphisa iingxaki ngenxa "yomgangatho" wokunyamezelana.

- Ukwenziwa komqulu kuyinkqubo yesantya esiphezulu.

- Ukwenza umqulu kunika abathengi ukugqiba umgangatho ophezulu. Oku kwenza ukuba umqulu wenze ukhetho olugqwesileyo lokuhombisa iinxalenye zentsimbi engenakutyiwa okanye kumacandelo afuna ukugqitywa okunje nge-anodizing okanye umgubo wokugquma. Kwakhona, ukuthungwa okanye iphethini inokugqithwa ebusweni ngexesha lokubumba.

- Ukwenziwa koluhlu kusebenzisa imathiriyeli ngokufanelekileyo kunezinye iinkqubo ezikhuphisanayo.

- Iimilo ezibunjiweyo eziqengqelekayo zinokuphuhliswa ngeendonga ezibhityileyo kuneenkqubo ezikhuphisanayo

Ukwenziwa komqulu yinkqubo eqhubekayo eguqula intsimbi ibe yimo eyenziwe ngobunjineli kusetyenziswa iiseti ezilandelelanayo zemiqulu edityanisiweyo, nganye kuzo isenza utshintsho olongezelelekileyo kwifomu. Isixa solu tshintsho luncinci kwifom yiprofayili enzima.

-

Ixabiso eliphantsi kakhulu Xn Z-Tshixa i-EPS ezenzekelayo kunye ...

-

UYilo oluHlaziywayo luka-2023 oluvela phezulu 20/40 FT Conta...

-

Umzi-mveliso ngokuthe ngqo eTshayina yale mihla yeSitayile seVilla yesinyithi...

-

Factory Supply ngokuzenzekela ngokugqibeleleyo Roll iMac...

-

Umgangatho ogqwesileyo we-XN1000 oGqwesileyo wophahla lweTile Makin...

-

China ixabiso elitshiphu eliphantsi Customizable Fireproof Galval...