*Iinkcukacha

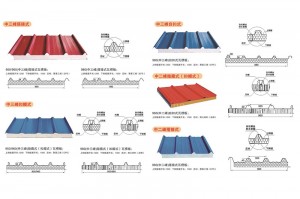

Umgca wokuvelisa ipaneli yeSandwich uyilelwe ngokukodwa ukuvelisa ibhodi ehlanganisiweyo yokugquma. Ngenkqubo yokulawula isantya esingenanyathelo, Iyakwazi ukuvelisa ipaneli ehlanganisiweyo edibeneyo ngokufanelekileyo ngexesha elinye. Umatshini wokwenza iipaneli zeSandwich ibe sisixhobo esiyimfuneko ekwenzeni iipaneli zophahla kunye neepaneli zodonga kwizityalo nakwiindawo zokugcina iimpahla, phakathi kwezinye izakhiwo.

*Iimbonakalo

*Iimbonakalo

1. Amandla ombane we-sandwich panel roll forming line yi-4k kunye nesantya sokuvelisa sifikelela kwi-6mmln. Ngenkqubo yokulawula isantya esingenasinyathelo, ukusebenza kakuhle komgca wokwenza umqulu kunokuzikhethela ngaphakathi kwe-O-6m mm.

2. ben ukuvelisa ipaneli yesandwich ye-EPS, isantya silawulwa ngokubanzi kwi-2-6 mm mm. Iyakuba ngaphantsi kancinane ukwenza ibhodi yoboya belitye (ixhomekeke kwiimfuno zokwenyani)

3. Umgca wokuvelisa ipaneli edibeneyo Uxhotyiswe nge-K.9 glue metering pump, ebonisa isantya esijikelezayo esisezantsi kunye nokuchaneka okuphezulu Iglue iyondliwa ngesantya se-0.1-2.0 kg mm. Ilawulwa yi-converter frequency.

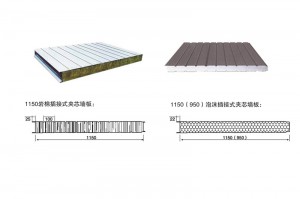

4. Ubukhulu bepaneli edibeneyo iyunithi yokwenza i-roll inokuvelisa iyahluka ukusuka kwi-50mm ukuya kwi-0mm. Ngokulungelelanisa i-rack ephezulu kunye nesezantsi, kunye nomgama phakathi komnini we-cutter kunye ne-rack feeding rack, sinokufumana iibhodi zesandwich ezinobunzima obuhlukeneyo kunye neenkcukacha.

5. Umthamo ofakiweyo uwonke: 34KW”; ubunzima bubonke (kubandakanywa nezincedisi): 17.5t.

6. Ubungakanani bomatshini wokwenza umqulu wephaneli: 12500 (16000 yeebhodi zoboya bamatye) X2200X2800; i-roll yangaphambili yohlobo lwe-5 uhlobo lwepaneli yesandwich ye-EPS ithatha i-shafts ye-rubber engama-23 kunye ne-160X80 yeetyhubhu zesikwere ezinobunzima be-6mm; I-rock yangaphambili yohlobo lwesi-7 yephaneli yoboya ehlanganisiweyo iqeshe iishafti zerabha ezingama-43, kunye neglue engaphezulu nasezantsi ezimeleyo yeglue Ixhotyiswe ngebhanti lokuhambisa loboya belitye eliyi-1. 7m, kunye nedayamitha yeshafti yokuqhuba ukuya kuba yi-30mm; ubude besakhelo somatshini Bufikelela kwiQm; umqulu wangaphambili Udityaniswe kunye ne-180X80 yeityhubhu zesikwere apho ubukhulu be-8mm.

*Iimfuno zeefektri

Iifektri apho kusetyenziswa oomatshini bethu bokwenza umqulu wesinyithi unokuba nophahla olusicaba okanye uhlobo oluthambekileyo. Ukuphakama kwe-cornice kufuneka kube mkhulu kune-3m, kwaye ububanzi obusebenzayo kufuneka bube ubuncinane be-45m. Umgangatho womzi-mveliso kufuneka ube sicaba kunye nekhonkrithi. Ukulungiselela isiseko somgca wokwenza umqulu, kuyafuneka ukuba uyilwe ngokwemizobo kunye ne-fmished ngaphambi kokuba izixhobo zifike. Unikezelo lwamandla lufuneka ukuba lube ngama-380 kwaye amandla afakiweyo ewonke yi-34kw. Kuyimfuneko ukuba i-facto ixhotyiswe nge-0.4-0.6MPa unikezelo lomoya olucinezelekileyo kunye nezixhobo zokukhanyisa. Umatshini wokwenza umqulu unika amandla afanayo kunye nezixhobo ezincedisayo. Ukuguquguquka kwamandla ombane kufuneka kungabi ngaphezu kwe-l0%, okanye kunokukhokelela ekusebenzeni okungaqhelekanga kwenkqubo.

I-stroke ayikho ngaphantsi kwe-29m, umthwalo wenkqubo yokuphakamisa mkhulu kune-5000kg, kwaye ukuphakama kokuphakamisa akukho ngaphantsi kwe-3.Qm. Ukuveliswa kunye nokugcinwa kwansuku zonke, malunga ne-8.10 abantu abafunekayo, kunye nabaqhubi be-3.4 kwezinye iinkqubo eziphambili zibandakanyiwe.

*Usetyenziso

Isixhobo esisecaleni sokutywina kwipaneli ye-rockwool

inkqubo yokusika

Iipompo zerabha ezine zilawulwa ziinjini ezimbini

Umphini werabha ongqindilili

Isixhobo sokusonga sombane

umatshini wokwenza umqulu

inkqubo yolawulo

Ibhanti lokuhambisa elongeziweyo

*Hambisa iimpahla

♦ INKONZO YENKAMPANI:

Hebei Xinnuo Roll Ukwenziwa Machine Co., Ltd., hayi kuphela ukuvelisa iintlobo ezahlukeneyo zoomatshini umqulu ukwenza umqulu, kodwa nokuphuhlisa imigca yemveliso okrelekrele oluzenzekelayo umqulu, C&Z imilo koomatshini purline, uhola wendlela guardrail umqulu ukwenza imigca umatshini, imigca sandwich panel imveliso imigca, decking oomatshini bokubumba, oomatshini bokukhanya, oomatshini bokwenza ucango lwe-shutter slat, oomatshini bombhobho osezantsi, oomatshini bokugalela amanzi, njl.

Izinto eziluncedo kumqulu wenza iMetal Part

Kukho iingenelo ezininzi zokusebenzisa ukwenza umqulu kwiiprojekthi zakho:

- Inkqubo yokwenza umqulu ivumela imisebenzi efana nokubetha, ukubethelwa, kunye ne-welding ukuba yenziwe e-line. Iindleko zomsebenzi kunye nexesha lemisebenzi yesibini ziyancitshiswa okanye zipheliswe, ukunciphisa iindleko zenxalenye.

- Isixhobo sokwenza umqulu sivumela iqondo eliphezulu lokuguquguquka. Isethi enye yezixhobo zefom ye-roll iya kwenza phantse naluphi na ubude becandelo elifanayo elinqamlezayo. Iiseti ezininzi zezixhobo zeendawo ezahlukeneyo zobude azifuneki.

- Inokubonelela ngolawulo olungcono lwe-dimensional kunezinye iinkqubo zetsimbi ezikhuphisanayo.

- Ukuphindaphinda kungokwemvelo kwinkqubo, ukuvumela ukudityaniswa lula kwamalungu aqulunqwe kwimveliso yakho egqityiweyo, kunye nokunciphisa iingxaki ngenxa "yomgangatho" wokunyamezelana.

- Ukwenziwa komqulu kuyinkqubo yesantya esiphezulu.

- Ukwenza umqulu kunika abathengi ukugqiba umgangatho ophezulu. Oku kwenza ukuba umqulu wenze ukhetho olugqwesileyo lokuhombisa iinxalenye zentsimbi engenakutyiwa okanye kumacandelo afuna ukugqitywa okunje nge-anodizing okanye umgubo wokugquma. Kwakhona, ukuthungwa okanye iphethini inokugqithwa ebusweni ngexesha lokubumba.

- Ukwenziwa koluhlu kusebenzisa imathiriyeli ngokufanelekileyo kunezinye iinkqubo ezikhuphisanayo.

- Iimilo ezibunjiweyo eziqengqelekayo zinokuphuhliswa ngeendonga ezibhityileyo kuneenkqubo ezikhuphisanayo

Ukwenziwa komqulu yinkqubo eqhubekayo eguqula intsimbi ibe yimo eyenziwe ngobunjineli kusetyenziswa iiseti ezilandelelanayo zemiqulu edityanisiweyo, nganye kuzo isenza utshintsho olongezelelekileyo kwifomu. Isixa solu tshintsho luncinci kwifom yiprofayili enzima.

-

umatshini wokumisa umthungo wepaneli yokwenza

-

umatshini wokwenza umqulu wephaneli yodonga

-

uhola wendlela guardriall roll eyenza umatshini onguhola wendlela...

-

umatshini wokwenza umjelo wegreenhouse gutter

-

manual sheet metal metal curving machine manufac...

-

Iipaneli zokuhombisa zoMgangatho Roll ukwenza umatshini wentsimbi ...