| HAYI. | Iparameter engundoqo yesixeko saseBotou ungqinisiso olufanelekileyo lwe-828 i-automatoc cinezela ibhlowu yenza i-joists ekhazimlisiweyo yentsimbi yophahla lwethayile ephuma kumatshini onece | |

| 1 | Ifanelekile ukuqhutyelwa phambili | Ipleyiti yentsimbi enombala |

| 2 | Ububanzi bepleyiti | 1000mm |

| 3 | Ukutyeba kwepleyiti | 0.3-0.7mm |

| 4 | De-coiler | Incwadi yokuqala, inokulayisha iitoni ezi-5 zemathiriyeli ekrwada |

| 5 | Iirola zokubumba | 12 imiqolo |

| 6 | Ububanzi be-roller | 80mm |

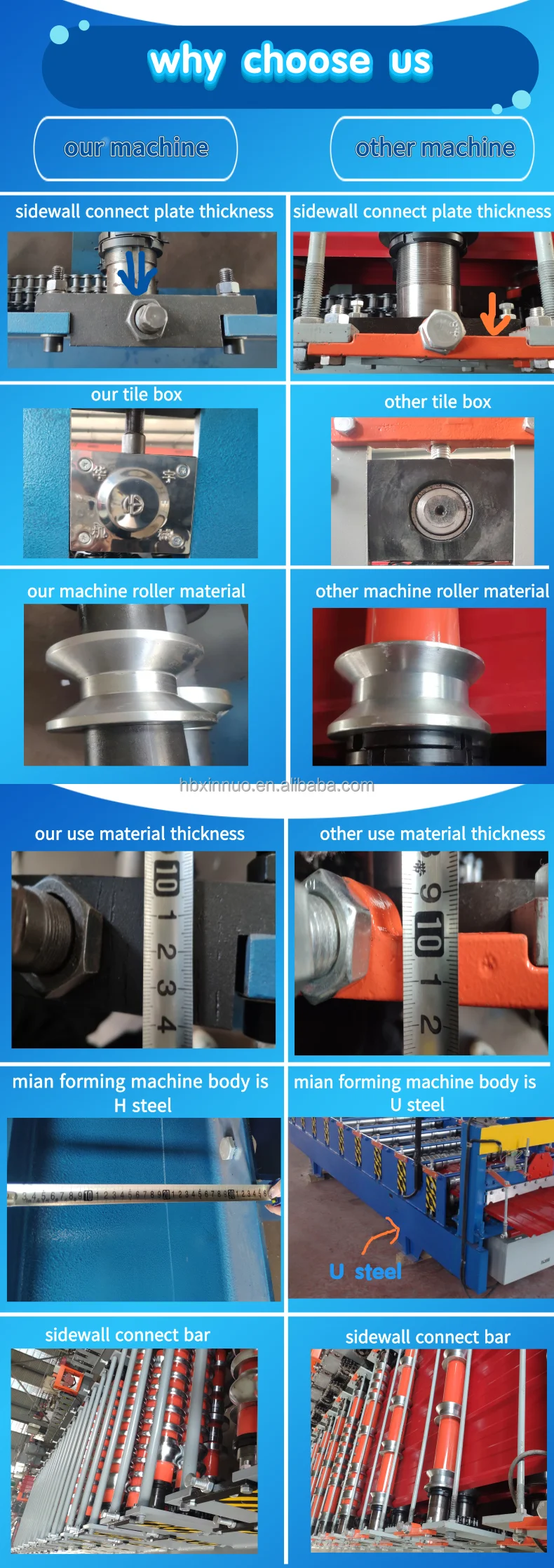

| 7 | Izinto eziqengqelekayo | Intsimbi yeCarbon 45# |

| 8 | Amandla enjini aphambili | 4kw |

| 9 | Imveliso | 0-3m/min |

| 10 | Indlela yokusika | Ukusika i-hydraulic mold |

| 11 | Izinto eziphathekayo ze-blade yokusika | Cr12 |

| 12 | Amandla okusika i-hydraulic | 3kw |

| 13 | Ukusetyenzwa ngokuchanekileyo | Ngaphakathi kwe-1.00mm |

| 14 | Inkqubo yokulawula | Ulawulo lwe-Delta PLC |

| 15 | Iphaneli yecala lomatshini | 14mm |

| 16 | Ubume obuphambili bomatshini | 300 H intsimbi |

| 17 | Ubunzima | Malunga ne-4.0T |

| 18 | Imilinganiselo | 7.0*1.5*1.55m |

| 19 | I-Voltage | 380V 50Hz 3 izigaba (ezitshintshekayo njengoko iimfuno) |

| 20 | Isatifikethi | CE/ISO |

| 21 | Isiko | Ngokweemfuno zomthengi |

| Iinkcukacha zokuPakisha: | Umatshini oyintloko uhamba ze, ibhokisi yokulawula ikhompyutha igcwele isakhelo somthi. |

| Umatshini oyintloko unqunu kwisikhongozeli, ibhokisi yokulawula ikhompyutha igcwele ukupakishwa kwamaplanga. | |

| Iinkcukacha zohambiso: | Iintsuku ezingama-20 |

♦ INKONZO YENKAMPANI:

Hebei Xinnuo Roll Ukwenziwa Machine Co., Ltd., hayi kuphela ukuvelisa iintlobo ezahlukeneyo zoomatshini umqulu ukwenza umqulu, kodwa nokuphuhlisa imigca yemveliso okrelekrele oluzenzekelayo umqulu, C&Z imilo koomatshini purline, uhola wendlela guardrail umqulu ukwenza imigca umatshini, imigca sandwich panel imveliso imigca, decking oomatshini bokubumba, oomatshini bokukhanya, oomatshini bokwenza ucango lwe-shutter slat, oomatshini bombhobho osezantsi, oomatshini bokugalela amanzi, njl.

Izinto eziluncedo kumqulu wenza iMetal Part

Kukho iingenelo ezininzi zokusebenzisa ukwenza umqulu kwiiprojekthi zakho:

- Inkqubo yokwenza umqulu ivumela imisebenzi efana nokubetha, ukubethelwa, kunye ne-welding ukuba yenziwe e-line. Iindleko zomsebenzi kunye nexesha lemisebenzi yesibini ziyancitshiswa okanye zipheliswe, ukunciphisa iindleko zenxalenye.

- Isixhobo sokwenza umqulu sivumela iqondo eliphezulu lokuguquguquka. Isethi enye yezixhobo zefom ye-roll iya kwenza phantse naluphi na ubude becandelo elifanayo elinqamlezayo. Iiseti ezininzi zezixhobo zeendawo ezahlukeneyo zobude azifuneki.

- Inokubonelela ngolawulo olungcono lwe-dimensional kunezinye iinkqubo zetsimbi ezikhuphisanayo.

- Ukuphindaphinda kungokwemvelo kwinkqubo, ukuvumela ukudityaniswa lula kwamalungu aqulunqwe kwimveliso yakho egqityiweyo, kunye nokunciphisa iingxaki ngenxa "yomgangatho" wokunyamezelana.

- Ukwenziwa komqulu kuyinkqubo yesantya esiphezulu.

- Ukwenza umqulu kunika abathengi ukugqiba umgangatho ophezulu. Oku kwenza ukuba umqulu wenze ukhetho olugqwesileyo lokuhombisa iinxalenye zentsimbi engenakutyiwa okanye kumacandelo afuna ukugqitywa okunje nge-anodizing okanye umgubo wokugquma. Kwakhona, ukuthungwa okanye iphethini inokugqithwa ebusweni ngexesha lokubumba.

- Ukwenziwa koluhlu kusebenzisa imathiriyeli ngokufanelekileyo kunezinye iinkqubo ezikhuphisanayo.

- Iimilo ezibunjiweyo eziqengqelekayo zinokuphuhliswa ngeendonga ezibhityileyo kuneenkqubo ezikhuphisanayo

Ukwenziwa komqulu yinkqubo eqhubekayo eguqula intsimbi ibe yimo eyenziwe ngobunjineli kusetyenziswa iiseti ezilandelelanayo zemiqulu edityanisiweyo, nganye kuzo isenza utshintsho olongezelelekileyo kwifomu. Isixa solu tshintsho luncinci kwifom yiprofayili enzima.

-

umphanda ngamacangci ophahla ishidi wenza umatshini sup...

-

umatshini wokugoba

-

c purlin machine

-

c purlin roll umatshini wokwenza

-

c purlin umatshini manual uphahla ithayile ukwenza umachin...

-

umatshini wokwenza itreyi yentambo

-

umatshini wokusika

-

umatshini wokugoba

-

umatshini wokwenza umqulu wephaneli wamacangci

-

cz i-purlin roll yenza umatshini we-iron sheet makin...

-

cz i-purlin roll yenza umatshini wokwenza i-mac...

-

umatshini wokwenza iithayile zomgangatho weprofi yesinyithi ...

-

Umatshini wokwenza uMgangatho wokuhombisa

-

umgangatho umatshini wokwenza umqulu womgangatho

-

umgca wokuvelisa i-foam shutter door

-

iprofayili yethayile ekhazimlisiweyo yokwenza umatshini wedrywall...